About This Project

The modern surfboard comprises layers of unrecyclable plastic which often break and pollute our oceans. Myco-composites provide the perfect foundation for a surfboard due to their lightweight construction and buoyancy. As we build a 100% biodegradable surfboard we investigate how low tech solutions of grown materials could compete with industry standard petroleum based materials for high performance sports, which can serve as a springboard for more complex experiments with fungal materials.

Ask the Scientists

Join The DiscussionWhat is the context of this research?

Sustainable materials are those employed in our consumer and industrial economies that can be produced in sufficient quantities without depleting non renewable resources or upsetting the environment and critical natural resource systems’ established steady-state balance. Modern society has adopted several tools made of materials that cause an imbalance in the environment, such as the surfboard, which is usually made with 3 different layers of plastic and has very little waste disposal solutions. Additionally, the average surfboard creates 375 pounds of CO2 emissions in the production process alone and uses toxic chemicals that can harm both workers and the environment. A mycelium based surfboard ‘blank’ can be grown into a mould and shaped without the need for harmful chemicals.

What is the significance of this project?

Large scale myco-composite sporting equipment such as Ecovative Surfboard and the Mushroom Canoehave explored the use of Ganoderma lucidum, a widely studied fungal strain for composite production, however the use of other strains could provide more suitable properties. A surfboard is a great experimental model to test frontiers in materials science due to scale, challenges in buoyancy, and exposure to extreme conditions such as intense sunlight, salt water and high impact force, broadening the range of possibilities for myco-composites from static into dynamic products. We will gain quantitative and qualitative scientific data on the flexural stability, fluid dynamics, mechanical and hydrophobicity properties of myco-composite tests both with and without an eco-resin coating.

What are the goals of the project?

Scaling up of myco-composites comes with its complexities and our team aims to develop a protocol and open source tools and machinery for this process. Determine which fungal strain and substrate is most suitable for producing a low-medium density blank for the surfboard. Investigate the possibility of embedding an organic textile during the growth process which could replace fibreglass. Evaluate the production and cost of a mycelium-based surfboard to consider whether it would be a viable alternative to conventional surfboards in terms of performance, cost, design, and environmental impact. We will work with surfboard makers to optimise the myco-composite by adding an internal skeleton or natural fibres to the material formula and ensure the surfboard performance is not compromised.

Budget

We will need to purchase several polypore strains. Initial testing can be done in house until we conclude two best performing strains. With changing seasons, one of our current limitations is controlling the growth conditions of our material, as fabricating large scale objects means we are unable to use conventional incubating systems. We would design and build our own incubator and dehydrator. The budget will also cover the costs of the Lab facilities over the next 9-12 months, and provide the raw materials required for testing and improving our substrates, and the organic textiles for replacing fibreglass. We will be outsourcing an Eco resin to laminate our board. To meet industry standards we will work with surf shapers and conduct mechanical and performance tests. Our staff fees will cover the cost for a minimum of 5-10 hours /week of lab work. Monitoring, documenting, data analysis, and maintenance will not be included in this.

Endorsed by

Project Timeline

Project Timeline

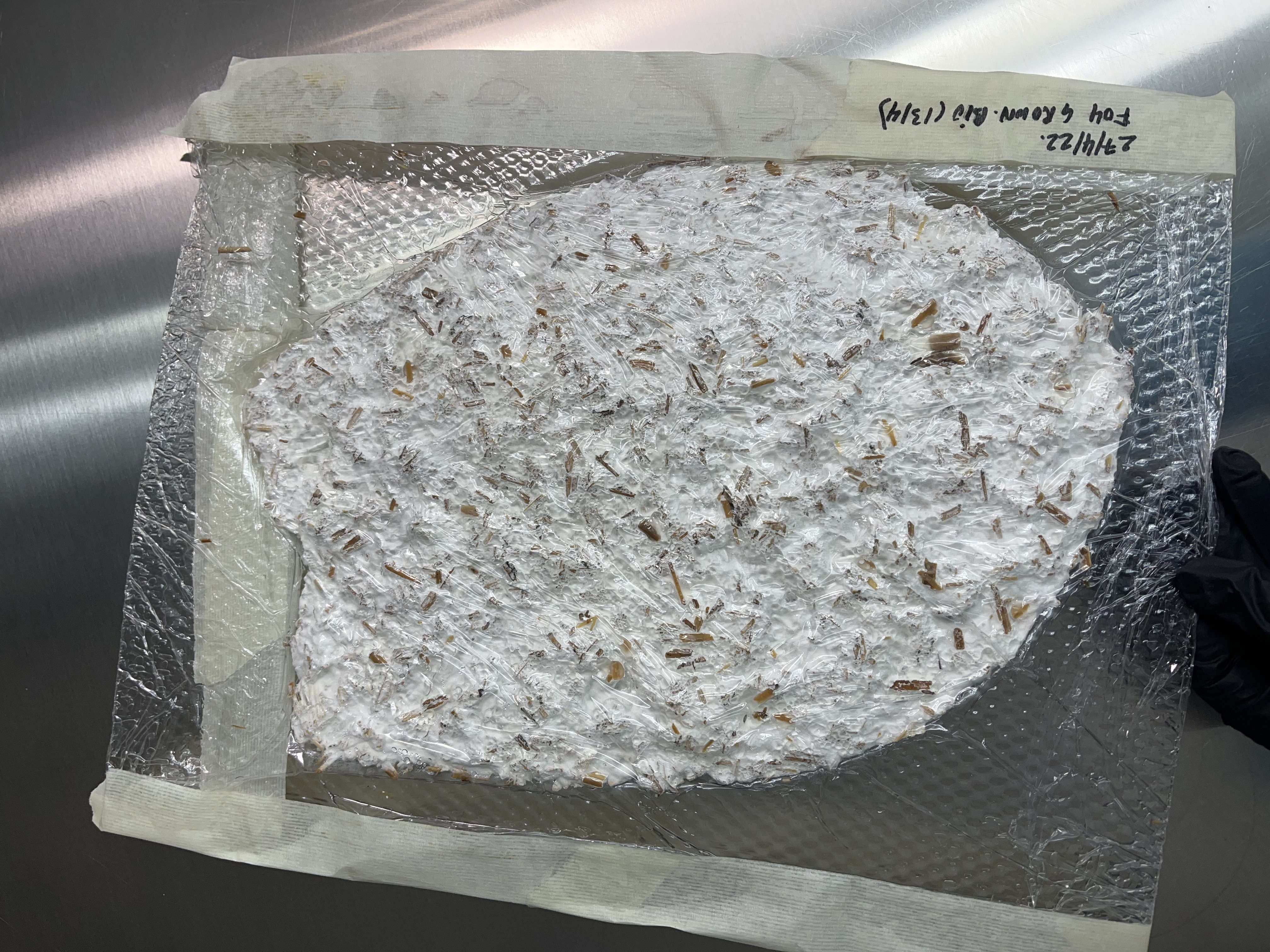

We have developed 1:100 and 1:2 scale prototypes of the ‘blank’ of the board, exploring different material formulas and fungal strains. Before we develop a 1:1 scale prototype, we will investigate which raw organic textile can be used to replace fibreglass and whether it can be embedded into the material during the mycelial growth process. We will document and record data collected during the research period and share the results through a landing page.

Aug 01, 2022

Determine material formula and fungal strain

Sep 08, 2022

Testing of mould designs at 1:2 scale

Sep 15, 2022

Fabricate incubation and dehydration space for 1:1 scale surf

Sep 15, 2022

Testing of embedding organic textile into growth process

Sep 15, 2022

Feedback from shapers to optimise material formula or include internal skeleton

Meet the Team

Team Bio

Our team come from different backgrounds, from architecture and fashion to business and food design. We are passionate about mushrooms and have worked together over the last 2 years on various mycelium related projects. Each team member brings complementary expertise to the development of the research and with the help of surfboard shapers we believe we can find a viable and sustainable alternative to plastic based surfboards.

Jessica Dias

Jessica is a biomaterial researcher, designer and architect. She advocates accessibility, bringing bio-design and biological sciences to a broader audience through creating wearable technologies that incorporate living organisms and biological processes.

Jessica forms part of Biobabes, a collective that was founded in 2015 who investigate and collaborate with living systems. She is currently working as an instructor and researcher in biomaterials, with an emphasis on myco-materials and has co-founded S-BIOTICA, a biodesign & material research hub in Barcelona.

Roberto Broce

Roberto Broce is a biodesigner and researcher focusing mainly on bioremediation of contaminated waterways and collaboration with organisms to create biomaterials. Roberto comes from a business background, having worked for many years in startup acceleration, venture capital, and business development. Through the lived experiences of the business world aimed at solving problems for the future, Roberto noticed an opportunity in creating and remediating materials that will stir us away from an increasingly plastic-averse market.

Roberto now works in the cultivation, research, and analysis of microorganisms as viable market alternatives for products containing a variety of synthetic polymers. Through design interventions with the users, Roberto is able to gain a first-person perspective on the living experiences of the end-user and how these designs might affect them.

Nacho de juan creix

Nacho is an entrepreneur specialising in disruptive and evolutive innovation. He has the ability to conceptualise and develop ideas in order to enrich innovation thinking and regennerative approach. As part of The Barcelona Foodture Summit, Nacho has a close working relationship with a wide range of innovators, engineers, researchers, chefs and product designers within the field of gastronomy. With over 15 years of experience in the creative industry, he has been able to translate his passion for science, art and technology into commercial products and experiences.

Nacho is the co-founder of Plat Institute, a creative platform that, through research and development, innovation and education, addresses the food and health problems that humanity will face in the future. Where professionals and food enthusiasts come together to learn, discover, create and prototype the future of food and health.

Additional Information

List of references

Appels, F., Camere, S., Montalti, M., Karana, E., Jansen, K., & Dijksterhuis, J. et al. (2019). Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Materials &Amp; Design, 161, 64-71. doi:

10.1016/j.matdes.2018.11.027

Asokana, P and Osmani, M. (2009). Assessing the recycling potential of glass fibre reinforced plastic waste in concrete and cement composites. Journal of Cleaner Production. 17 (9), 821-829

Attias, N., Danai, O., Abitbol, T., Tarazi, E., Ezov, N., Pereman, I., & Grobman, Y. (2020). Mycelium bio-composites in industrial design and architecture: Comparative review and experimental analysis. Journal Of Cleaner Production, 246, 119037. Doi: 10.1016/j.jclepro.2019.119037

Audy J K, Haines T (2004), Surf equipment, design, materials and construction Published by Edith Cowan University

Barbero, EJ (1999) Introduction to Composite Material Design, Published by Taylor and Francis Group, First Edition

Bourne, L and Milner, J. (1963). Polyester Resin Hazards. Industrial Journal. 20 (1), 100

Carlsson, L A and Pipes, R B (1987). Experimental Characterization of Advanced Composite Materials. New Jersey: Prentice-Hall, Inc.. 43-53.

Chou TW, Kelly A, Zweben C (Editors) (2000) Comprehensive Composite Materials- Volume 1: Fibre Reinforcements and General Theory of Composites, Published by Elsevier Science Ltd, First Edition

the Eden Project. (2007). Eden rides sustainable surfing wave at Rip Curl Boardmasters. Available: http://www.edenproject.com/media/archive/2007/Eden-at-Rip-CurlBoardmasters.php. Last accessed 29/06/2022

Factory Media. (2009). Quivers. Available: http://surfersboardguide.com/quivers. Last accessed 29/06/2022.

Fulbright, J. (2017). The Surfboard: A Greek Tragedy. Retrieved 15 June 2022, from https://www.surfspecialties.co...

Johnson, Ian (2005), Surfboard Design and Construction, Self Published, 1st Edition

Martin, J (2007), Material Benefits Towards Greener Surfboards, The Surfers Journal, Volume 16, Number 6, pg 87-97

Mohanty AK, Manjusri M, Drzal LT (2005) Natural Fibres, Biopolymers, and Biocomposites, Published by Taylor and Francis

Mohantya, AK, Misraa, M and Hinrichsen, G. (2000). Biofibres, biodegradable polymers and biocomposites: An Overview. Macromolecular Material Engineering. 276/277 (1), 1-24.

Roylance, D (1996). Mechanics of Materials. Chichester: John Wiley and Sons, Inc. 22-40.

Rizov, V, Shipsha, A and Zenkert, D. (2005). Indentation Study of Foam Core Sandwich composite panels. Composite Structures. 69 (1), 95-102

Shaw, Stephen (1994), Surfboard, Published by Stephen M Shaw

Steeves, CA and Fleck, NA (2004). Collapse Mechanisms of Sandwich Beams with Composite Faces and Foam Core, Loaded in Three-point Bending. Part 1: Analytical Models and Minimum Weight Design. International Journal of Mechanical Sciences. 46 (1), 561-583.

Wool R, Sun X S (2005) Bio-Based Polymers and Composites, Published by Elsevier Academic Press

Zhao, H., Nam, P., Richards, V., & Lekakh, S. (2018). Thermal Decomposition Studies of EPS Foam, Polyurethane Foam, and Epoxy Resin (SLA) as Patterns for Investment Casting; Analysis of Hydrogen Cyanide (HCN) from Thermal Degradation of Polyurethane Foam. International Journal Of Metalcasting, 13(1), 18-25. doi: 10.1007/s40962-018-0240-5

Project Backers

- 40Backers

- 105%Funded

- $6,835Total Donations

- $170.88Average Donation