Project Results

During this research, I was able to investigate further the use of the mycelium from basidiomycetes and ascomycetes in the remediation amorphous polymers in an agar setup and of cotton and synthetic textile fibers. This crowdfunding campaign allowed me to develop a mycelium materials lab, develop a protocol for producing mycelium skins in a liquid fermentation setup and identify upcoming challenges to be able to work on textile remediation, such as crystallinity or fitness of the strain used. This project was an opportunity to bring my postgraduate thesis project further and I am now going to dig deeper into the subject of textile bioremediation by doing a PhD at the Vrije Universiteit Brussels.

Thank you all again for your support and for following my mushroom adventures !

About This Project

Can textile waste be repurposed and recycled as a raw material for the growth of mycelium leathers? Textile waste is accumulating in landfills due to overcunsumption of garments and poor recycling opportunities. Textile biodegradation by various fungal strains (Pleurotus ostreatus, Schyzophyllium comune and Omphalatus nidiformis) will be assessed to find the most efficient strain to biodegrade denim and synthetic textile waste, and which is best for myco-leather production.

Ask the Scientists

Join The DiscussionWhat is the context of this research?

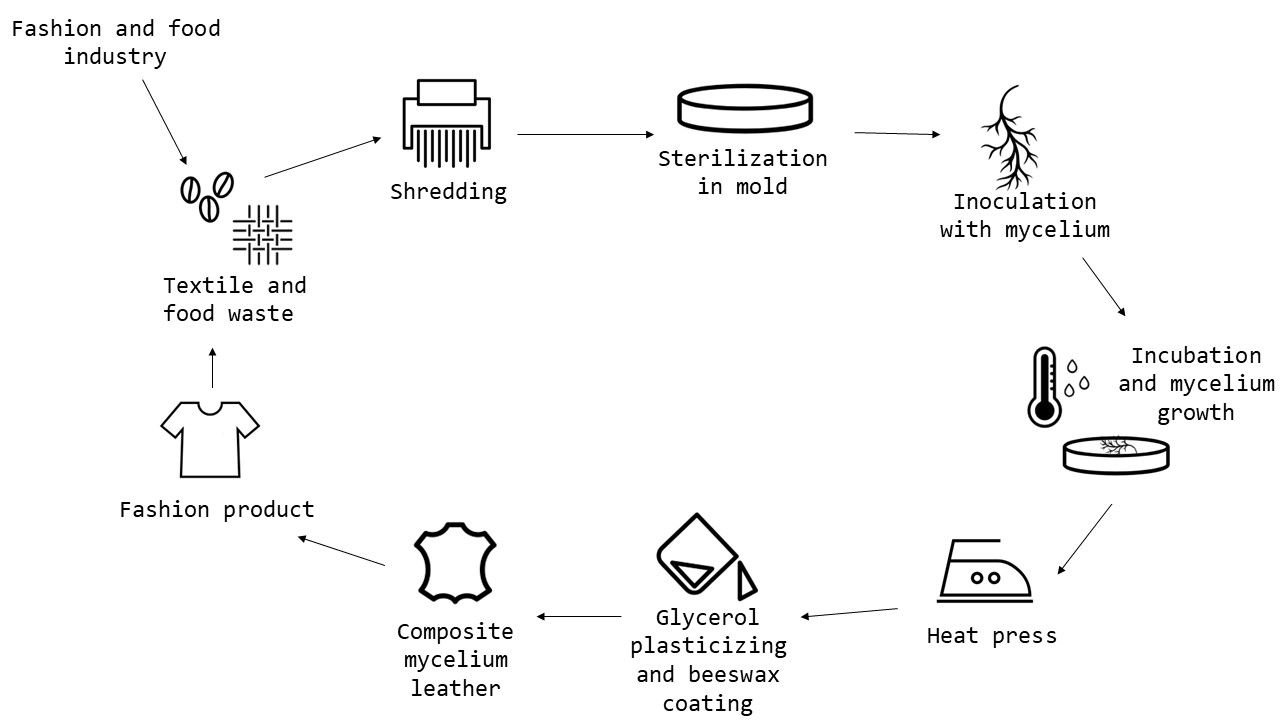

This experiment was based on the previous observations that most fungal strains are able to biodegrade cellulose but also different types of plastic (PUR and PET), which are the main components of textile. Mycelium is also used for the production of leather-like materials by various companies. In previous experiments, samples of composite flexible mycelium materials were produced through the biodegradation of combinations of denim or synthetic textile waste, food waste and spent coffee grounds using the mycelium of P. ostreatus (oyster), at the scale of a petri dish. Provided the soft nature of the substrate, the composite material was malleable, and therefore interesting for further textile applications.

What is the significance of this project?

The fashion industry produces over 100 billion garments per year, of which 60% are plastic based and 85% will end up in a dump before the end of the year. Considering that various micro and macro-organisms, such as fungi and more specifically mycelium, are capable of biodegrading cellulose and complex plastic molecules, an opportunity to rethink the linearity of the textile industry emerges. Beyond breaking down the waste products, the mycelium hyphae network can produce mycelium-based materials, including leather-like materials, adoptable in the fashion industry. Producing a composite mycelium leather from the textile waste, forming a new textile from it and repeating the loop represents a way to eliminate the accumulation problem and replace it with natural solutions.

What are the goals of the project?

The first goal is to compare the biodegradation of denim textile waste and synthetic textile waste by P. ostreatus, O. nidiformis and S. comune in petri dishes (3 replicates for each textile type and for each strain) using the velocity of colonization as a criteria. Second is to enhance the quality of the composite leather already developped by repeating the previous experiments in an incubator controling temperature, humidity and CO2. Third, to enhance the quality of the composite leather already developped, especifically the resistance to tearing by felting the fibers prior to inoculation, using the best strain. And last, to upscale the size of the composite leather production to reach 3 sheets of 50cm x 50cm and make a design object out of it (bag).

Budget

Through previous experiments, DIY (Do It Yourself) scientific tools were used and these low means already led to promising results. However, to test more rigorously the hypothesis, to test the upscaling of the already functionning experiments and to push the experimentations further, professional scientific tools are required (CO2 incubator, laminar flow hood with UV sterilization, autoclave), hence the location of a ready-equipped biology lab in a startup incubator.

Since this project is combining biology and textile research and developpement, a part of the budget will also be allocated to the purchasing of tools for pre-treatment of the textile waste (purchase a textile shredder) and for the post processing of the final product (heat press).

Shape of the glassware was proven to play an important role in constraining the growth of mycelium and thus in the quality of the final product, hence its cusom production by a glass blower.

Endorsed by

Project Timeline

Project Timeline

The length of the project greatly depends on how long it take the mycelium to biodegrade the textile and of the contamination that could interfere with the experiment. I am considering each experiment to be done growing for periods between 30 and 40 days considering I want to use good quality scientific tools. Experiments by the end of the project are also expected to take longer as reports will have to be written, and winter religious festivities are expected to happen.

Aug 06, 2022

Project Launched

Jan 16, 2023

Starting of the project. Preparation of growth mediums and waking-up of the mycelium strains to be grown on agar.

Jun 30, 2023

Results: what strain was the best for biodegrading each textiles and for making mycelium leather.

Aug 26, 2023

Researching on pre-processing of the textile waste: how to shred it more efficiently and felting the waste fibers with the nearest textile research center (EURECAT)

Sep 08, 2023

Launching of the "growth on felted textile" experiments using the results of the previous experiments. Incubation for ~30 days

Meet the Team

Annah-Ololade Sangosanya

Annah-Ololade is a Bioengineer and a Textile designer by training (M. Eng in biology, INSA Toulouse and Fabricademy textile and technology academy postgraduate, IAAC Barcelona). Her fields of expertise are microbiology, fermentation processes, genetic engineering but also digital fabrication, 3D design and rapid prototyping. She is a curious mind always willing to explore how science and design can be used in synergy to develop sustainable solutions to our current problems.

Her current focus is on microbiology, biomaterials and biodesign as she recently onboarded two ambitious projects: a PhD on textile waste biodegradation using mycelium at the Vrije Universiteit Brussels while simultaneously working on the EU funded WORTH partnership project, in which she is developing fashion accessories grown from flexible mycelium materials.

Additional Information

The strong points of this project is that it offers an alternative to the linear fashion model by creating a textile grown from textile waste, closing the loop and entering the field of bioremediative design. The post processing used only uses natural materials and no plastic coating, unlike most cruelty-free leathers.

For more information on the project, here is a link to my postgraduate thesis and its supplementary data. Information can also be found on my webpage.

Project Backers

- 44Backers

- 102%Funded

- $3,432Total Donations

- $78.00Average Donation